Custom Blending

JBT Corp develops, blends, and manufactures extruded and molded dry friction materials in-house.

We offer insight on material choices based on each customer’s application. Our team will provide customers with samples to ensure materials are well-suited to their designs and testing.

Our proprietary friction material compounds are precisely measured, weighed, mixed, extruded and cured to meet the customer’s requirements for:

- Coefficient of friction

- Wear characteristics

- Durometer/Density

Our experts can customize a wide range of material characteristics based on the specific requirements of your product.

Bonding and Surface Treatment

The fundamentals of what John McGourthy Sr. developed in his kitchen oven in the 1970s is what JBT Corp uses to this day to ensure a high-quality bond. Markets such as lawn and garden, hoist and crane, and industrial applications have come to rely on our bonding capabilities.

For a good, durable bond it is vital to begin with thorough surface preparation. How we clean, remove oils and abrasively open the surface creates superior crosslinking of the adhesive between the friction material and steel substrate. At JBT Corp we achieve a premium bond by utilizing automation where possible in the surface preparation processes such as:

- Through feed aqueous wash

- Rotary sandblasting

- Laser etch removal

After the surface preparation is done the parts are ready for bonding. With over 45 years of experience, JBT Corp has developed several thermosetting adhesives for both shock resistance and flash curing. The proprietary designed fixtures used and quantity of parts that can be bonded at one time are crucial to reaching a quality bond. For materials with a faster curing time, JBT Corp has developed flash bonding techniques using our Custom Pick and Place Robotic Bonder and our Semi-Automated Rotary Bonders. We stand by our proprietary bonding processes and techniques.

When compared to traditional bonding methods, our processes have proven to be more efficient and cost effective for our customers.

Engineering and Design Support

- JBT Corporation has adopted the latest in non-destructive gauging techniques and equipment to allow for advanced material development.

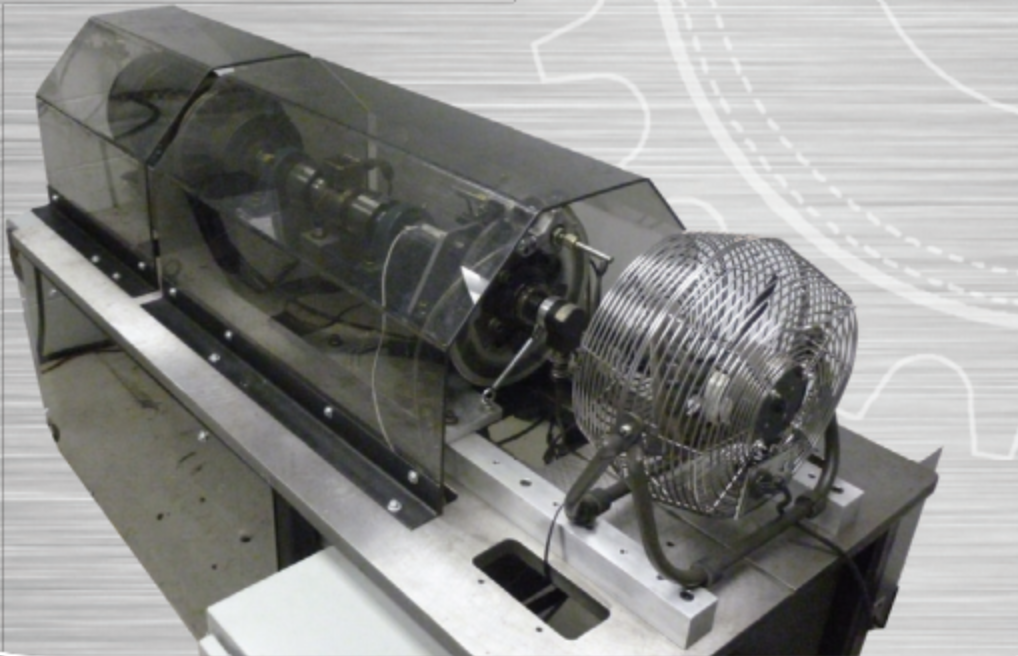

- Standardized product testing is available onsite with state-of-the-art dynamometers.

- Specialized customer-specific dynamometers are developed and fabricated with our test equipment group.

- JBT has close relationships established with accredited outside testing labs to supplement any required customer requirements.

- JBT offers engineering assistance at whatever level you require. Among the services we provide are the review of applications, material recommendations, and analysis of designs for cost optimization.

- We’re also able to modify our equipment to match specific operating requirements. And in many cases, we’ve installed customer equipment in order to perform specific application testing.

- Rigorous testing in our own labs assures uniform results before production begins, and continuous checks throughout the manufacturing process ensure product integrity.

- Our Research and Development Center provides first-quality answers to your bonded clutch and brake needs. The Center houses our own custom-designed and built state-of-the-art dynamometer for evaluating friction material performance. It delivers infinitely variable speed control, constant torque at any level and is operated and monitored in a way that allows virtually any set of variables to be examined during testing.

The JBT Corporation Difference

Producing quality components is an essential part of our culture at JBT Corporation. That is why we believe in proper preparation for each project, as well as proper finishing. Coupled with our bonding skills we can offer you protective coating, plating, or assembly for your parts.

To see how our bonding capabilities can support your project, please contact us today.